Add to Cart

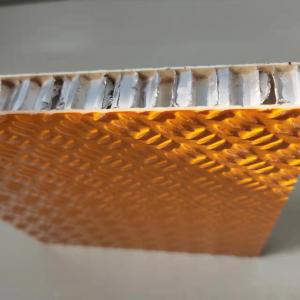

High Strength Glass Fiber Aluminum Honeycomb Panel For Yacht Deck

1. Descriptions:

The fiberglass honeycomb panel (FRP honeycomb panel) consists of two glass fiber (FRP) panels on the upper and lower surfaces, which are laminated to the aluminum honeycomb core with two-component PU glue or epoxy glue. Fiberglass (FRP) is lightweight, high strength, low cost, and resistant to aging. It is a new type of environmental protection material.

FRP honeycomb panel has the characteristics of not easy to deform, low thermal conductivity and good thermal insulation performance. It is mainly used in truck bed, RV, yacht deck and van panel. FRP honeycomb panels are wear-resistant, yellowing resistance, aging resistance, high temperature resistance, high mechanical strength, good impact toughness, smooth surface and easy to clean.

2. Specifications:

| Carbon fiber honeycomb panel | |

| FRP | Skins of High Pressure Laminate |

| Thickness: from 1.0 mm to 2 mm | |

| - Other thickness on request | |

| - Black color or customizable | |

| HONEYCOMB CORE | 3003 Aluminum Honeycomb Core |

| Diameter (hexagonal cells): Ø 6, Ø 10 | |

| Foil Thickness: from 40 to 80 microns | |

| FRP | Skins of High Pressure Laminate |

| Thickness: from 1.0 mm to 2 mm | |

| - Other thickness on request | |

| - Black color or customizable | |

| Total Panel thickness | Regular: 5mm, 8mm, 10mm, 20mm |

| -Other thickness on request | |

| Dimension | Regular: 1220*2440mm |

| -Other dimension on request | |

| Specific specification of honeycomb core | |||||

| Side length(mm) | 4, 5, 6, 7, 8, 9, 10, 12, 15, 20, 50 | ||||

| Foil thickness(mm) | 0.04, 0.05, 0.06, 0.07, 0.08, 0.1, 0.15, 0.2 | ||||

| Alloy | Al3003 | ||||

| Supply form | Unexpanded(block, strip) or expanded(slice); | ||||

| Technical Data Sheet | |||||

|

Specification | Side length (mm) | Density (kg/m³) | Compression strength (MPa) | L-Shear strength (MPa) | W-Shear strength (MPa) |

| BHC3003-5-0.03 | 5 | 27 | 0.53 | 0.44 | 0.24 |

| BHC3003-5-0.04 | 5 | 31 | 0.66 | 0.53 | 0.3 |

| BHC3003-4-0.03 | 4 | 33 | 0.73 | 0.58 | 0.33 |

| BHC3003-4-0.04 | 4 | 39 | 0.98 | 0.75 | 0.43 |

| BHC3003-5-0.05 | 5 | 41 | 1.07 | 0.8 | 0.47 |

| BHC3003-3-0.03 | 3 | 44 | 1.18 | 0.89 | 0.52 |

| BHC3003-5-0.06 | 5 | 49 | 1.43 | 1.03 | 0.60 |

| BHC3003-3-0.04 | 3 | 52 | 1.6 | 1.15 | 0.67 |

| BHC3003-4-0.05 | 4 | 53 | 1.65 | 1.18 | 0.69 |

| BHC3003-4-0.06 | 4 | 61 | 2.07 | 1.48 | 0.86 |

| BHC3003-5-0.08 | 5 | 67 | 2.45 | 1.74 | 1.02 |

| BHC3003-3-0.05 | 3 | 68 | 2.50 | 1.78 | 1.04 |

| BHC3003-Beecore Aluminum Honeycomb Core, 3003 Series | |||||

3. FRP honeycomb panel has several advantages:

• Super light and high strength, anti-fatigue

• Excellent environment adaptability and electric insulating

• Outstanding corrosion resistance and flame resistance

• Good compression and impact resistance

• Sound and heat insulation

4. Applications:

• Truck body, yacht deck, Partition, stone reinforcement, medical, automotive, industrial, sports, Kitchen countertop etc.

5. Quality control:

A very technical engineering team. The general manager has worked in the Netherlands. The core technologies are introduced from the Netherlands. Others are very young and have more than 5 years of practical experience.

Strict QC team: 8 people are responsible for FRP honeycomb panel of quality control of parts, processing, testing, packaging, etc.

6. FRP honeycomb panel of more pictures:

7. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin (Dutch) International Group which was founded in 1957. It is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc.

8. Factory show

9. FAQ

Q1. What is FRP honeycomb panel usd for?

A: The FRP honeycomb panel is used for industrial, truck, kitchen countertop.

Q2. What are the advantages of FRP honeycomb panel?

A: FRP honeycomb panel has the advantages of light weight-high strength, high surface flatness, environmental protection and no pollution.

Q3. What is the packaging method of FRP honeycomb panel?

A: FRP honeycomb panel of samples are packed in cardboard and bulk orders are packed in plywood cases.